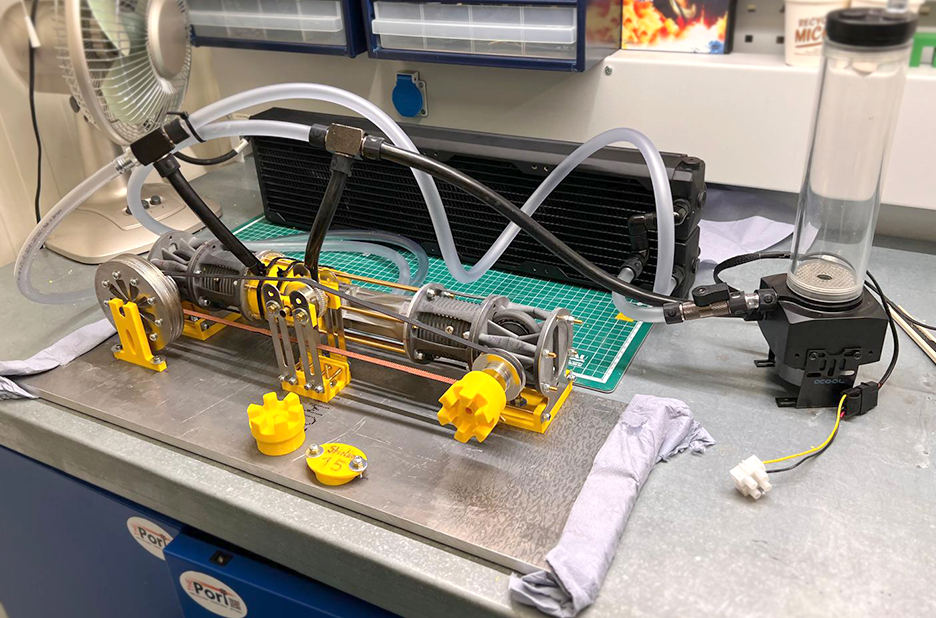

Prototype profile: Stirling cryo-cooler

A Stirling machine is a device, that can be used as a heat pump to effectively cool down a given system. In reverse it can be used to generate electricity out of a heat source. It was invented 200 years ago and has not been improved/changed greatly since then, as there was never an economic interest.

This project focuses on the redevelopment of a version of a Stirling machine utilizing modern manufacturing methods. The aim is to improve the machine well enough in terms of power and efficiency, that it could be used as a more environmentally friendly method to cool down experiments at CERN to their operating temperatures. Various ideas have been conceptualized and started. Currently the focus lies on fabricating improved heat exchangers (which are important components of a Stirling machine) utilizing an exotic method called electroforming. The process has to be developed to fulfil the tight requirements needed to provide reliable components.

Prototype by Oliver Skura