Prototype profile: Adjustable Height Table for Wire Bonding

Prototyping makes up one of the key pillars of IdeaSquare. A recent prototype, started in March 2023, is in collaboration with the experimental physics department and BONDLab.

BONDLab provides AI Wedge Wire Bonding services to all CERN-related projects, providing guidance and support in the layout of detector modules and their components, in particular to wire bonding issues, and the design and construction of wire bonding support tooling.

Name of the prototype: Adjustable Height Table for Wire Bonding

Wire bonding is at the forefront of what happens in BONDLab. Aluminium wedge bonding is performed at ambient temperature using pressure and ultrasonic energy to form wire bonds.

The Bond Lab uses various machines. The Die Bonder CAMMAX DB 600 is used to attach silicon chips to a substrate. The Wire Bonder, DELVOTEC G5 is also used at BONDLab. The machine has limited movement in the z-axis (up/down) and therefore custom-made adjustable height table is required to perform bonding for various CERN projects.

What’s the challenge?

BONDLab has already an adjustable height table created earlier for the machine, however, to maintain high precision bonding it is necessary to build a new modified adjustable height table for the machine.

Prototype development

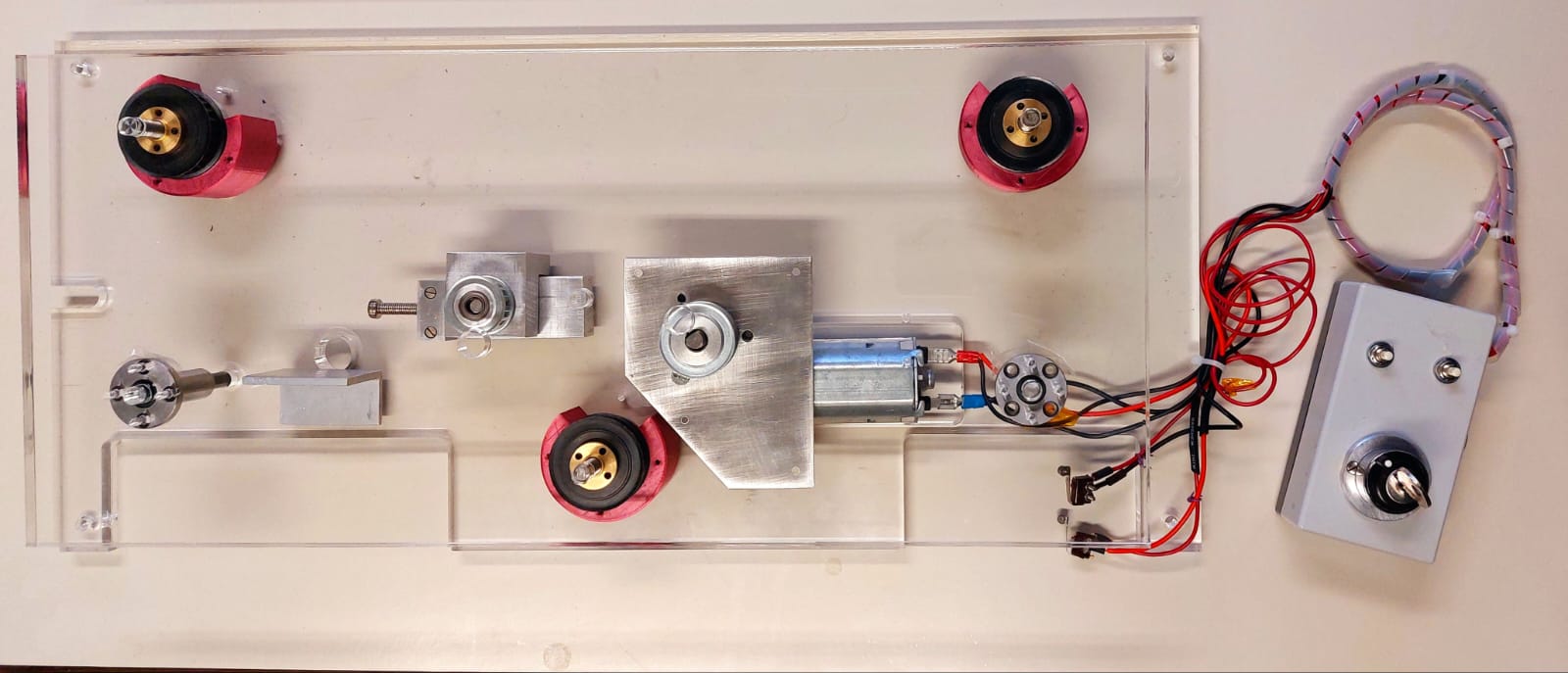

The prototype uses Plexi plates produced using the laser cutting machine at IdeaSquare. The plates are financially viable to produce, and are efficient to determine if the design is correct before the prototype is sent for final production.

The prototype will continue its development in Autumn 2023, and from there, the team at Bond Lab can build an aluminium version later this year.